DIAMOND

DIAMOND

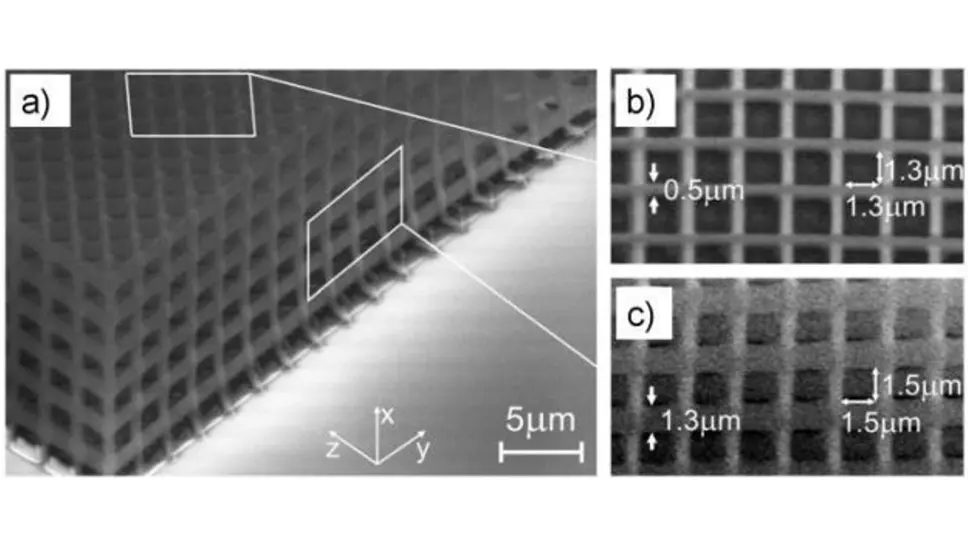

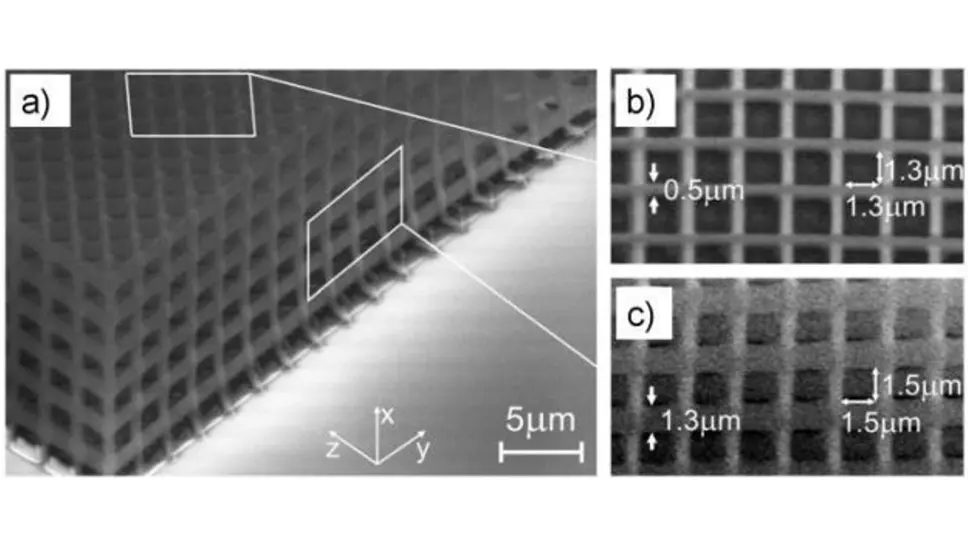

The fabrication of micro/nano-structures by two photon polymerization (2PP) is an innovative technique that allows the realization of 3D devices with high resolution, with applications in the fields of photonics, micromechanical systems and lab-on-chip technology. The mechanism of two photon absorption allows the selective polymerization of small focal volumes, with dimensions under the diffraction limit, and the realization of structures at different depths without affecting the surrounding material. By moving the focal volume inside the photosensitive resist, it is possible to define arbitrary geometries. After a first irradiation, the unpolymerized material is removed with a solvent, leaving only the desired structures. Some potential applications are 3D micro-scaffolds for stem cells culture, fabrication of microoptical components, and metamaterials.

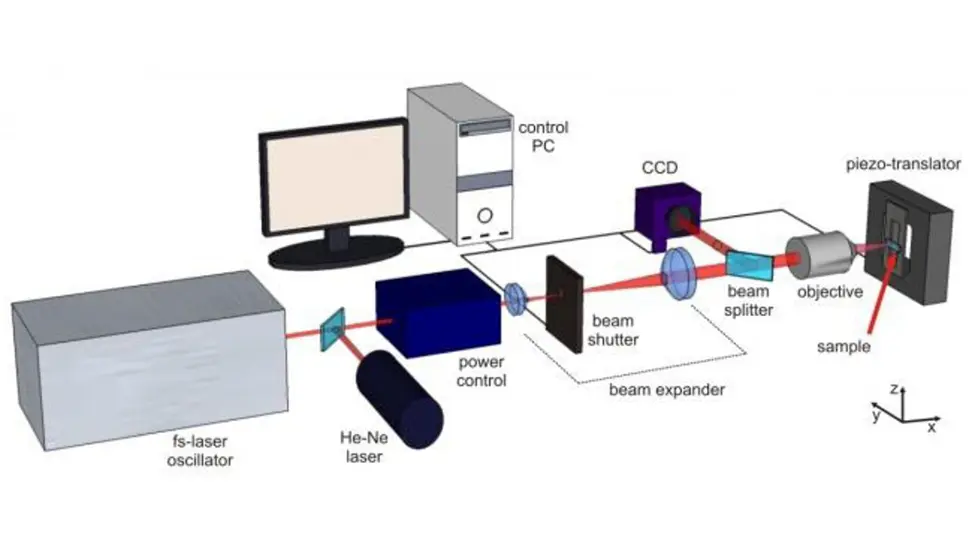

Equipment

The laser source used for 2PP fabrication is a frequency-doubled erbium-doped fiber laser (TOPTICA). The laser, working in mode-locking regime, emits pulses of 100 fs with a repetition rate of 100MHz, at a central wavelength of 780 nm a and average power of 150 mW. The laser beam passes through a galvanomagnetic laser shutter (Altechna) and through a telescope for beam expansion. The power can be controlled by an attenuation stage composed by a polarizer and a mechanically controlled waveplate. The sample is mounted on a piezoelectric 3-axes translator with nanometric resolution. The beam is focused inside the sample with a high NA oil immersion objective (Plan-APOCHROMAT 100x 1.4 NA, Carl Zeiss AG). The structures are realized in a hybrid organic-inorganic solgel resist (SZ2080), specifically developed for 2PP. The final devices are visualized with a scanning electron microscope (SEM).