SNOW

SNOW

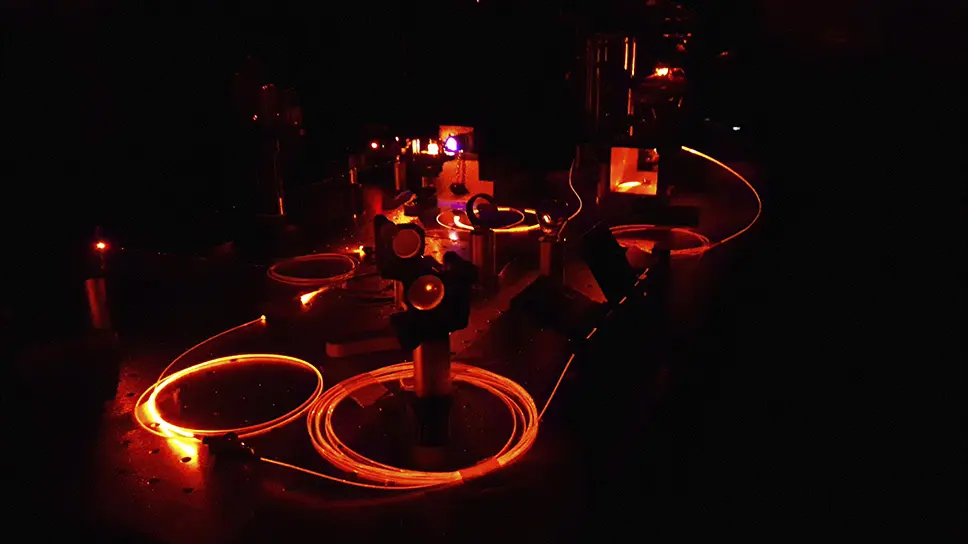

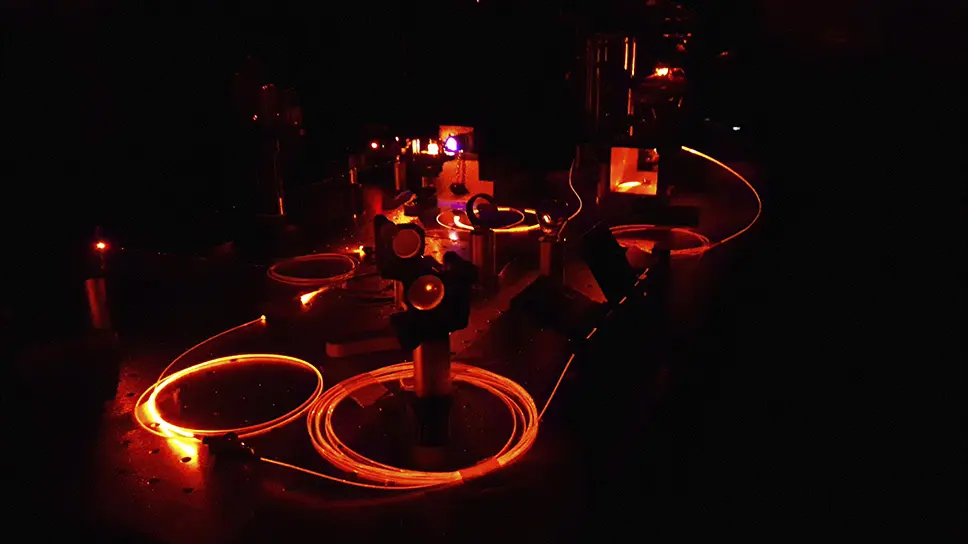

The SNOW laboratory allows to perform the optical characterization and the permanent connectorization of integrated devices, both photonic and optofluidic, fabricated by femtosecond laser micromachining in glasses or crystals. In fact, for being useful in their actual applications, the integrated devices should be connected to optical fibers, both for injecting the input light and collecting the output, and to microtubes for supplying liquids in the microfluidic circuits.

Equipment

The laboratory is equipped with the necessary instrumentation for guaranteeing both a semi-automatic characterization and a stable connectorization of integrated circuits with a high precision.

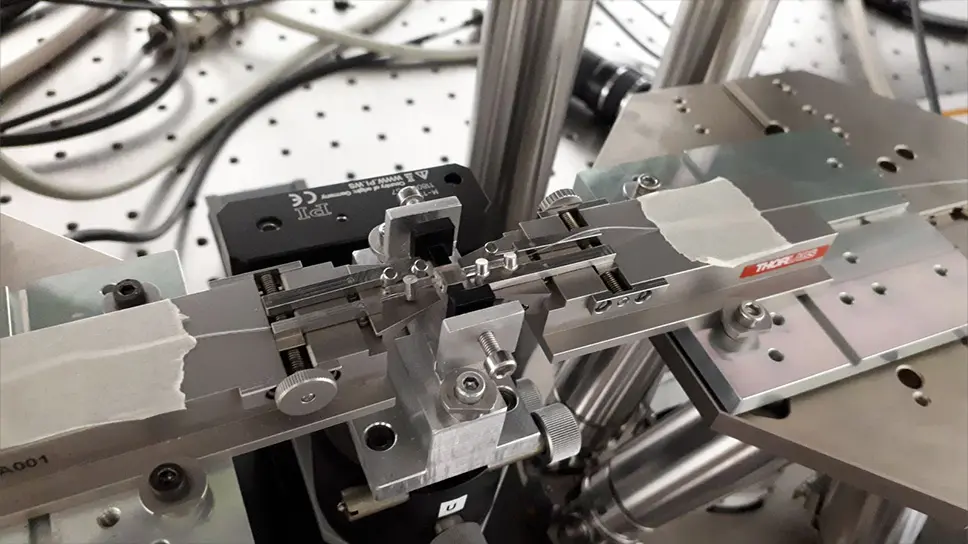

There is a workstation for the relative positioning and the accurate alignment of the device with the other components (fibers and microtubes) to connect. The system consists of two hexapod translators (PI), with six degrees of freedom each (three translations and three tilts), and two additional linear translators. The motion precision of the mechanical actuators is lower than 200 nm. Two cameras with a macro objective provide a visual monitoring, from two different points of view, of the alignment and gluing process. In terms of magnification, this system is comparable with an optical microscope.

There are then different CW laser sources for the optical characterization of the devices and for optimizing and testing their optical connections. In addition to many laser diodes working in the near infrared, it is worth citing a solid-state laser source with a wavelength of 607 nm, employed for the classical characterization of integrated quantum memories.

Finally, an LED lamp with emission in the near UV is present for the photopolymerization of the resin employed for gluing fibers and microtubes.

Research projects

PRIN 2017 - QSHIP

Find out more